Reinforced Ralumac - with the addition of steel mesh reinforcement

![]()

|

Reinforced Ralumac - with the addition of steel mesh reinforcement

|

|

Ralumac with Mesh Mesh Track is a steel reinforcing overlay for cracked or deformed roads, which has been successfully used for some years. Used in combination with Ralumac it can deal with problems such as reflective cracking, slippage, deformation or differential movement.

Application : The galvanised steel mesh is laid directly onto the surface of the road which should be cleaned. However, if there are deep deformations in the road surface or heavy damage such as rutting then a regulating layer should be applied first. The mesh is unrolled onto the surface and flattened to it by a roller. The mesh is then fixed using hilty type nails after which Ralumac is applied. Once Ralumac has hardened then Asphalt or Bitmac can be laid to a minimum thickness of 50mm. Depending on design a second layer can be applied. Mesh Track is available in two grades which limits deformation in an overlay to a minimum. |

Makeup of steel reinforcement overlay

|

|

In some peat

roads severe cracking can be observed due to large variations in seasonal

moisture content. To rectify this problem one possible solution is to

excavate to a significant depth and replace with a bituminous material,

this can be a costly process. A cheaper alternative is to reinforce the

existing surface with a steel mesh which provides significant strength

to the existing surface.

This is tacked to the road surface with ralumac and at least a further 50mm of Bitmac is applied. Several test sites have shown the steel reinforcement to be superior to other reinforcement materials. The woven hexagonal wire netting, manufactured out of heavy galvanised steel wire, is reinforced at regular intervals by transverse twisted steel wire strands, interwoven into the mesh. The construction of Mesh Track allows the product to be securely tensioned whilst deformation is prevented by the transverse wire strands. |

|

|

|

|

Examples of typical peat roads

|

||

|

||||||||||||||

|

Reinforced Ralumac - with the addition of fibres

|

|

|

Ralumac with Fibres Ralumac with Fibres is the ultimate cold laid Asphaltic material incorporating polymer modified binder, fibres and high quality aggregate. Specially designed and developed for highly stressed roads which require a long lasting and stable surface.

|

|

Ralumac with fibres on a highly stressed roundabout |

|

|

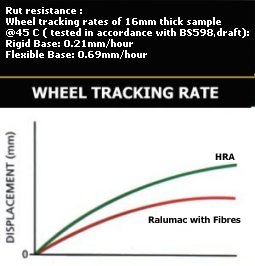

Ruts are

the sure sign that the ever increasing number and weight of heavy vehicles

are slowly breaking down our road structures. The immediate response before

the seal is broken and greater damage is caused is to fill, level and

eliminate the rut. Over the past 35 years Ralumac has proven in Ireland

and many countries to be the tough economical solution to a major problem.

Ralumac is laid in two layers. The first layer/coat can take out ruts up to 75mm, if greater depths are required a second base layer can be applied followed by a wearing/top coat giving an excellent riding surface which is waterproof with great texture. Solve your rut problem with Ralumac. For highly

stressed sites where rutting is an obvious problem, the best solution

is to use Ralumac with fibres. This will restore the profile of the road

and provide a significant reduction in further rut resistance.

|

|

Fibres are added to the final layer of Ralumac to provide a reinforcement which not only improves tensile strength but also improves texture. This is normally applied to highly stressed sites such as roundabouts or steep carriageways for improved braking perfomance. Ralumac with fibres can be laid with a single layer of material on many roads which have a good shape ( and therefore a regulating layer is not required ) or where traffic volumes are low. Coverage rates will vary accordingly. |

|

|||||||||||||||||||||||||||||