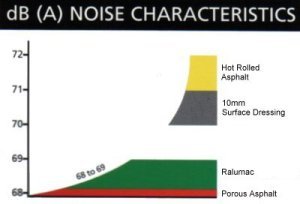

Ralumac - The all-round solution to problems all round

![]()

Ralumac is a cold-applied asphaltic material, designed for more demanding locations on all types of surfaces. It gives a superior surface with good texture and is therefore suitable for a whole range of road maintenance problems faced by today's Road Engineer.

Ralumac's effectiveness as an overlay carpet is derived from thoroughly researched and developed Bitumen Emulsion. This is a Polymer Modified Binder which, when mixed with selected high quality aggregates and fillers, gives a material with good stability in summer whilst maintaining flexibility in winter.